Accurate monitoring key to sector efficiency

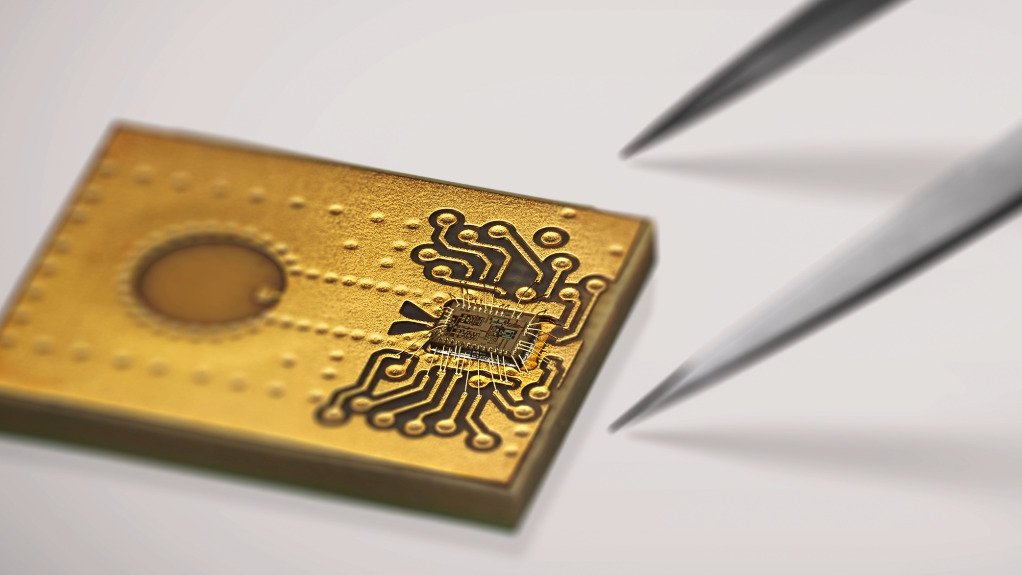

HEART OF THE SENSOR VEGA's sensors are engineered to ensure accuracy and reliability in harsh environments through its radar chip

With sub-Saharan Africa experiencing an increase in infrastructure development, the increased demand for cement necessitates precise monitoring to ensure that the storage and transportation thereof can efficiently meet the demand, says sensor and measuring instrument manufacturer VEGA marketing manager Miguel Petersen.

Urbanisation and infrastructure expansion are driving growth in the region’s cement industry. The continent’s production capacity has increased from 262-million tonnes a year in 2014 to 386.1-million tonnes in 2024, VEGA says, adding that producers need more storage capacity. Cement is stored in silos and transported using pneumatic conveying systems. To manage these processes effectively, it is crucial to ensure accurate level measurement, point level detection, and pressure monitoring, says VEGA.

“Inaccuracies in level measurement or pressure monitoring can result in inefficiencies, costly disruptions, or even equipment failure,” the company adds.

Petersen notes that such inaccurate measurement can cause significant operational challenges, such as stock shortages that, in turn, can result in demand not being met.

Further, plants often struggle with overfilling, pipeline blockages and inaccurate level readings, owing to dust interference. These issues slow production and increase maintenance.

Precise monitoring can ensure efficiency and prevent costly disruptions, Petersen adds.

VEGA Range

To tackle these challenges, VEGA offers its VEGAPULS 6X radar sensor, VEGAWAVE 62 vibrating level switch, and VEGABAR 82 pressure transmitter to enhance materials handling and ensure operational efficiency.

The sensors are engineered to ensure accuracy and reliability through their radar chips in environments with extreme dust and temperature fluctuations.

Designed by VEGA, the chip functions as the “heart of the sensor” and enables the sensor to meet the company’s standards for precision, largely owing to its self-diagnosing capabilities during operation. This feature enables continuous monitoring of the sensor’s accuracy and performance.

“The inherent simplicity of installing the sensor makes it easy to fine-tune and calibrate, in line with the individual challenges presented by various applications,” Petersen adds.

Further, VEGA’s scalable solutions can be implemented across a range of plant sizes, supporting small producers and major manufacturers.

The company’s sensor range also supports the cement industry’s transition towards more sustainable and low-carbon production practices. Its sensors provide real-time process monitoring and accurate data, forming the foundation for sustainable process optimisation.

VEGA’s level and pressure sensors enable cement producers to reduce the use of raw materials, in addition to minimising waste, Petersen elaborates.

The sensors also help to control inventory levels, consequently preventing material overflow and reducing losses.

The VEGAPULS 6X radar sensor provides non-contact level measurement in cement silos. Unlike traditional measurement devices, it is unaffected by dust, buildup or process conditions, providing precise and continuous readings.

Accurate inventory management enables operators to optimise material flow and prevent storage-related inefficiencies.

The radar sensor measures liquids and solids, regardless of whether the material is hot, cold, hazardous or corrosive.

A key advantage of the sensor is its very small blocking distance, making it ideal for measuring bulk solids at close range.

To prevent overfill, producers can install the VEGAWAVE 62 vibrating level switch, which detects high levels of cement in the silo, consequently preventing spills and improving safety. Its robust design withstands heavy dust exposure, ensuring reliable operation without the risk of false alarms caused by buildup.

In the pneumatic conveying system, the VEGABAR 82 pressure transmitter monitors pipeline pressure. With its high overload resistance, it helps to maintain the stable transport of cement, which, in turn, prevents blockages and reduces equipment wear. Reliable pressure monitoring ensures that the system operates efficiently; this reduces downtime and improves overall plant performance.

Implementing these measurement solutions enables operators to focus on productivity rather than troubleshooting equipment issues.

As cement producers aim to optimise production processes and safeguard their workers, VEGA’s technology and expertise continue to set the standard, paving the way for advancements that go beyond “just bricks and mortar”, Petersen concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation